An angle pulse valve is crucial for controlling fluid flow in various systems, yet many overlook its unique benefits. Are you ready to discover how this valve can enhance your operations?

An angle pulse valve regulates the flow of fluids or gases, providing precise control and effective shut-off capabilities in both residential and industrial applications.

Understanding the mechanics behind angle pulse valves reveals their importance in maintaining efficiency and safety in piping systems. Dive deeper to explore their features, advantages, and best practices for selection and maintenance.

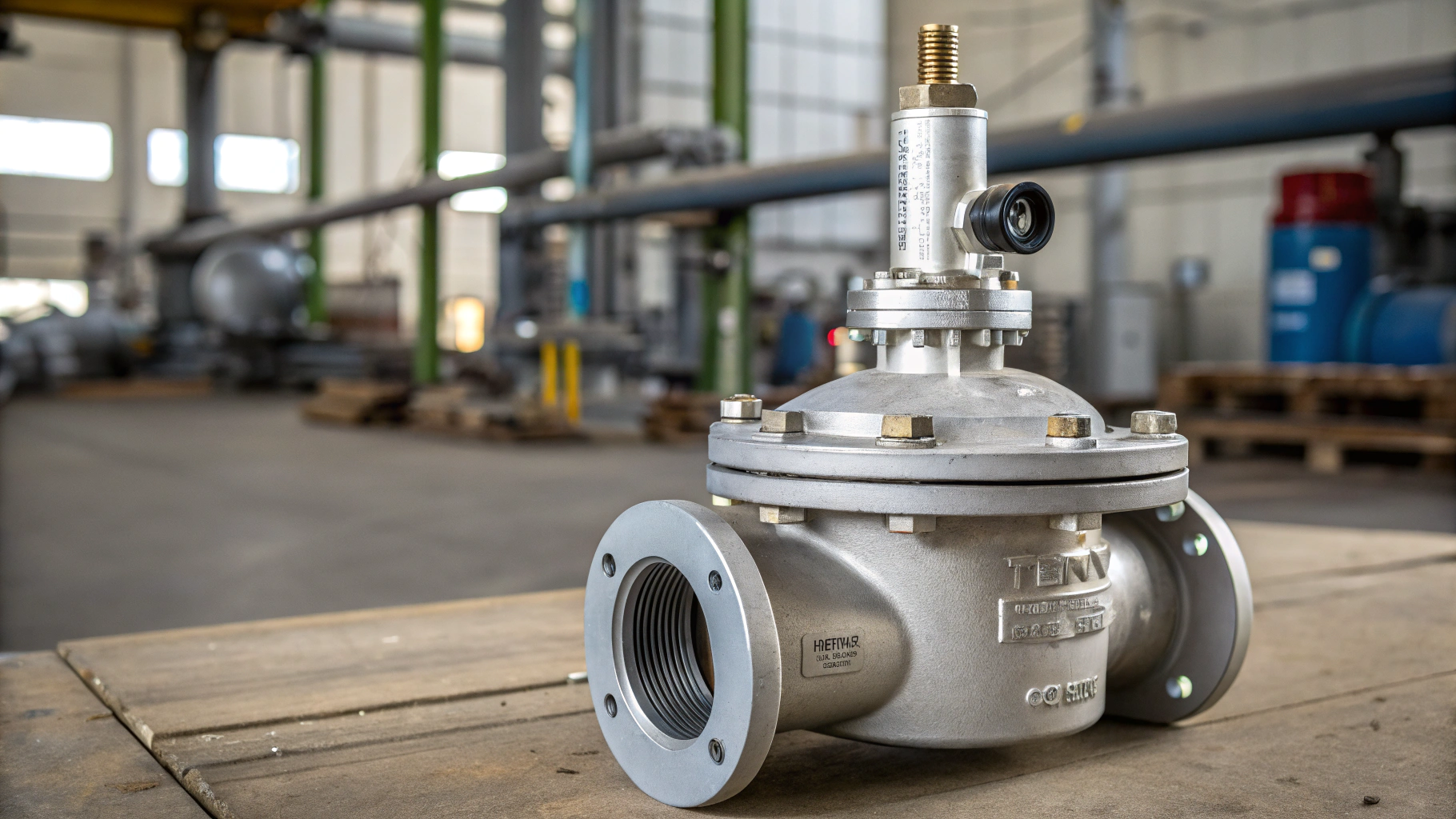

What Makes the TORK Power Pulse Solenoid Valve Unique?

The TORK Power Pulse Solenoid Valve1 stands out for its ability to deliver compressed air in short bursts, making it essential for various industrial applications.

The unique 90-degree inlet and outlet design2 allows this valve to create a pressure imbalance that opens the diaphragm momentarily when energized, producing a powerful air pulse. This feature is particularly useful in dust filtration systems3 across industries like cement4 and glass5, where it helps dislodge accumulated dust from filters.

The TORK Power Pulse Solenoid Valve operates effectively by requiring a minimum pressure differential. It can be configured with time relays6 for automated control or used as standalone components to protect against environmental factors. Its single or double diaphragm designs cater to different operational needs, ensuring versatility in application. The valve's ability to function under high-pressure conditions makes it ideal for controlling compressed air rather than liquids. Regular maintenance is crucial to ensure optimal performance and longevity of the valve in demanding environments.

How Do Angle Valves Enhance Plumbing Efficiency?

Angle valves7 are essential in plumbing systems. They control water flow effectively and provide quick shut-off during emergencies. This ensures safety and efficiency in water management.

Angle valves feature an L-shaped design8 that connects the inlet and outlet at a 90-degree angle. This configuration allows for efficient flow regulation while minimizing pressure loss. They are commonly made from durable materials like brass9, which resists corrosion and extends their lifespan. Regular maintenance is necessary to prevent leaks or failures, ensuring they function optimally over time.

In addition to residential use, angle valves find applications in industrial settings10 where controlling liquid or gas flow is critical. Their ability to quickly shut off supply makes them indispensable during repairs or emergencies, enhancing overall plumbing efficiency and safety across various environments.

| Feature | Description |

|---|---|

| Design | L-shaped for efficient flow control |

| Material | Typically brass for durability |

| Application | Residential and industrial plumbing |

| Maintenance | Regular checks to prevent leaks |

Understanding how angle valves work can help you make informed decisions about your plumbing needs, ensuring effective water management in any setting.

What Are the Key Maintenance Tips for Angle Pulse Valves?

Maintaining angle pulse valves11 is crucial for their performance and longevity. Neglecting maintenance can lead to costly failures and downtime.

Regular maintenance of angle pulse valves involves checking for leaks, ensuring proper alignment, and cleaning components. Inspect seals and diaphragms for wear. Replace any damaged parts promptly to avoid further issues. Additionally, keep the valve body clean from dust and debris to ensure smooth operation.

To maintain optimal performance, schedule routine inspections12 every few months. This helps identify potential problems early on. Use appropriate lubricants13 on moving parts to reduce friction and wear. Ensure that the pressure settings are within recommended limits to prevent damage from overpressure situations. Lastly, document all maintenance activities14 for future reference and compliance with industry standards. Regular attention will extend the life of your angle pulse valves significantly, saving time and money in the long run.

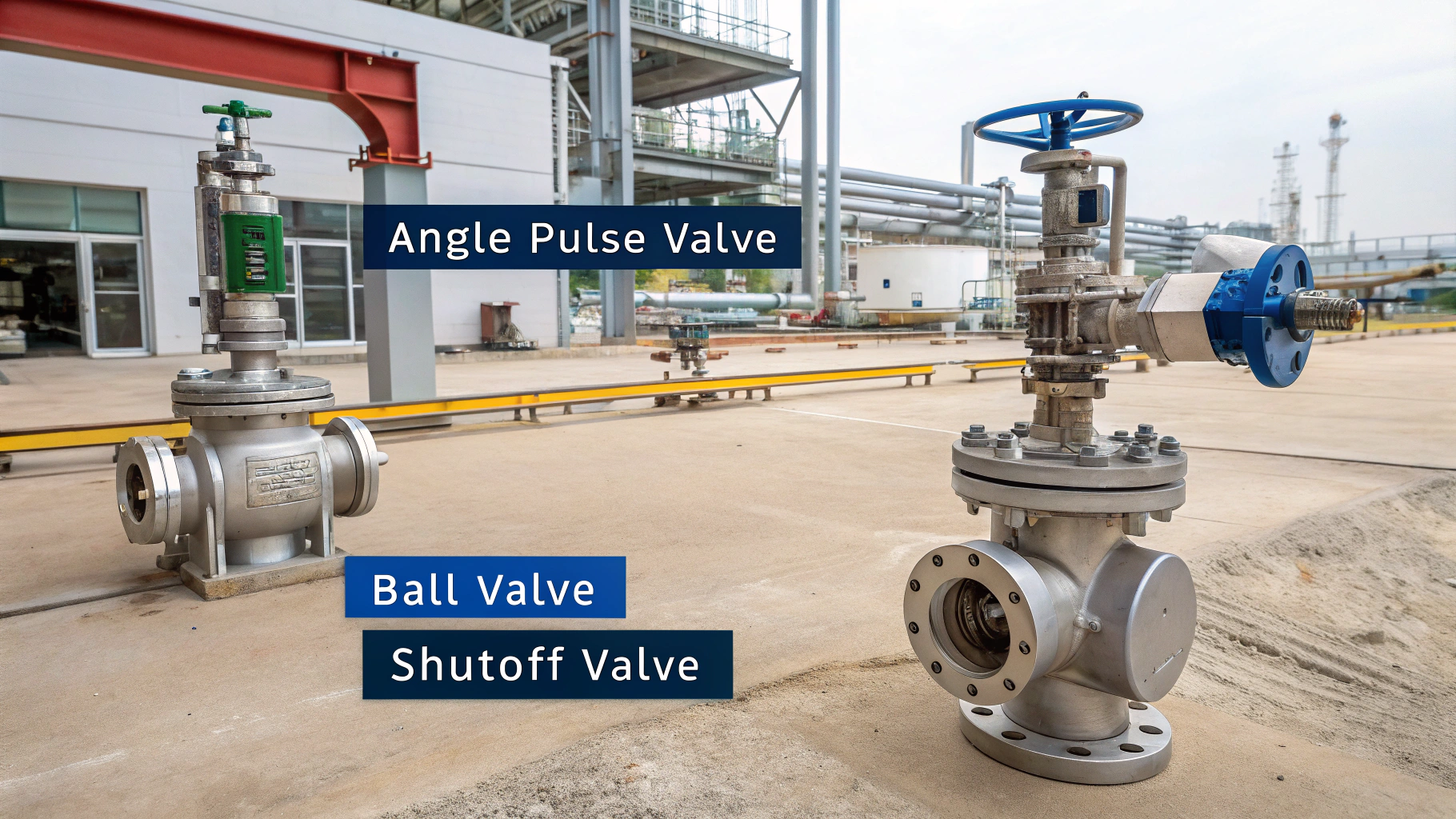

How Do Angle Pulse Valves Compare to Other Valve Types?

Angle pulse valves are essential in various applications, but how do they stack up against ball valves15 and shutoff valves16? Understanding their differences can save you time and money.

Angle pulse valves are designed for specific tasks like controlling compressed air in dust filtration systems, while ball valves excel in rapid flow changes. Shutoff valves serve emergency needs by stopping flow quickly.

When comparing angle pulse valves to other types, consider their unique functionalities. Angle pulse valves operate using a pressure imbalance that creates short bursts of air, making them ideal for cleaning filters in industrial settings. In contrast, ball valves provide a quick on/off function with minimal resistance, suitable for high-flow applications. Shutoff valves focus on safety by isolating sections of a system during emergencies.

| Valve Type | Key Functionality | Best Applications |

|---|---|---|

| Angle Pulse Valve | Short bursts of air for cleaning | Dust filtration systems |

| Ball Valve | Quick on/off control | High-flow liquid or gas applications |

| Shutoff Valve | Emergency isolation | Plumbing systems requiring immediate stop |

In summary, each valve type has its strengths and weaknesses based on the application requirements. Understanding these differences helps ensure you choose the right valve for your needs.

Conclusion

The TORK Power Pulse Solenoid Valve delivers powerful air pulses for dust filtration, while angle valves enhance plumbing efficiency through precise flow control and quick shut-off.

-

Discover the unique features of the TORK Power Pulse Solenoid Valve and its role in delivering air pulses for industrial use. ↩

-

Learn about the impact of the 90-degree inlet and outlet design on creating pressure imbalance in solenoid valves. ↩

-

Understand how pulse valves like the TORK Power Pulse Valve are used in cleaning and maintaining dust filtration systems. ↩

-

Learn how pulse valves assist in dust removal and filter maintenance in cement production. ↩

-

Find out how pulse valves help maintain clean air and system efficiency in glass manufacturing environments ↩

-

Explore how time relays automate the control of solenoid valves for improved system performance. ↩

-

Learn about the function and importance of angle valves in plumbing systems. ↩

-

Understand the advantages of the L-shaped design in angle valves for efficient flow regulation. ↩

-

Explore why brass is chosen for angle valves due to its corrosion resistance and durability. ↩

-

Learn about the industrial applications of angle valves and their importance in flow control systems. ↩

-

Understand the function and importance of angle pulse valves in various systems. ↩

-

Learn about the recommended maintenance schedule and inspection frequency for angle pulse valves. ↩

-

Discover the best lubricants for maintaining smooth operation in angle pulse valves. ↩

-

Understand the importance of documenting maintenance activities for compliance and efficiency. ↩

-

Learn about the versatility and functionality of ball valves in various systems. ↩

-

Understand how shutoff valves help isolate parts of a system to prevent damage during emergencies. ↩